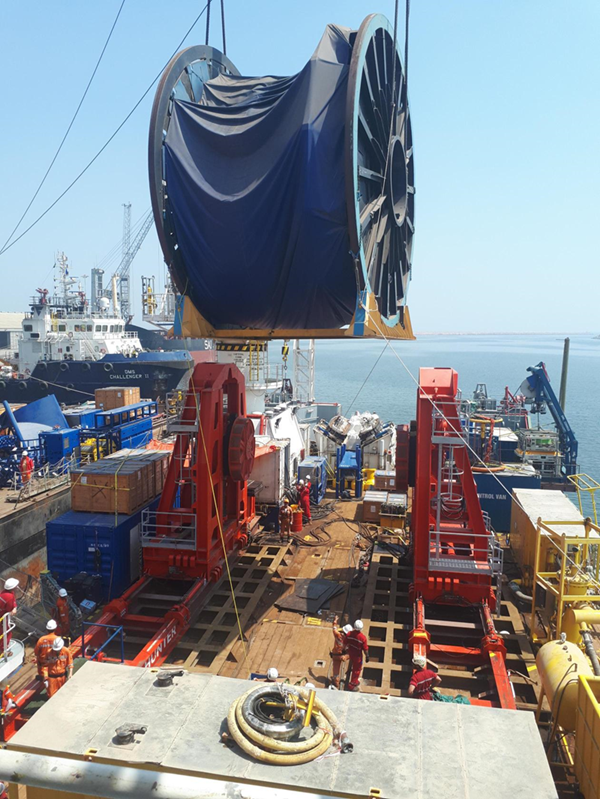

450Te REEL DRIVE SYSTEM DESIGN-BUILD

Demonstrating Motive’s proven track record in the design, build, and operation of a high-performance Reel Drive System for flexible, umbilical and cable recovery projects.

Overview

REEL DRIVE SYSTEM - KEY FEATURES

450Te Total Capacity (Reel + Product)

Twin Screw Jacking System provides large vertical jacking travel to accommodate all standard reel sizes

Rotate reels in either direction to deploy/recover product

Heavy duty drive units enable large line pulls for applications without tensioners

Constant Tension or Manual Mode

Reel Drive System controls can be linked to deck tensioner for a fully synchronised, failsafe, lay spread

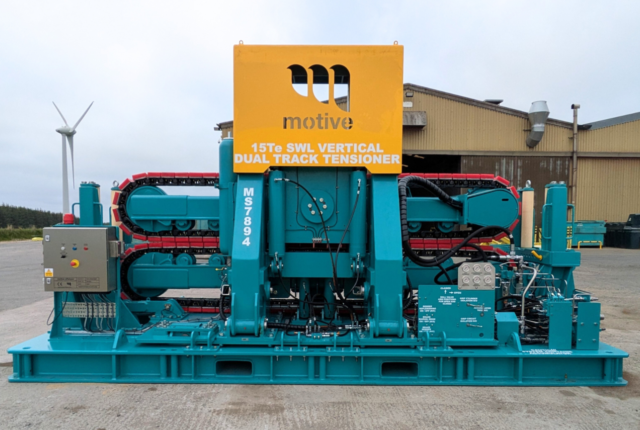

Modular Reel Drive System for easier transport with rapid assembly/demob

In co-operation with our client, Motive designed, manufactured and operated key items of equipment, including a 15Te Horizontal Tensioner, 10Te Vertical Tensioner, 450Te Reel Drive System, and a 5000Te Carousel Loading Tower. All items were robustly built to a high-quality specification, with the Motive team working flexibly to achieve demanding delivery schedules.

Multi-disciplinary Personnel

Benefit from a team of experts with extensive hands-on Reel Drive System experience.

Our Reel Drive Systems are backed by a global pool of multi-disciplinary technicians who own the entire process.

From mobilisation and installation to product spooling and equipment operation and maintenance, this integrated expertise ensures maximum project efficiency and safety, delivering 24/7 offshore support.