MOTIVE HORIZONTAL LAY SYSTEM: GULF OF AMERICA

By combining Horizontal Lay Systems, Tensioners, and all supporting equipment in one robust package, Motive delivers streamlined, ready-to-deploy lay solutions.

Overview

EQUIPMENT SUPPLIED

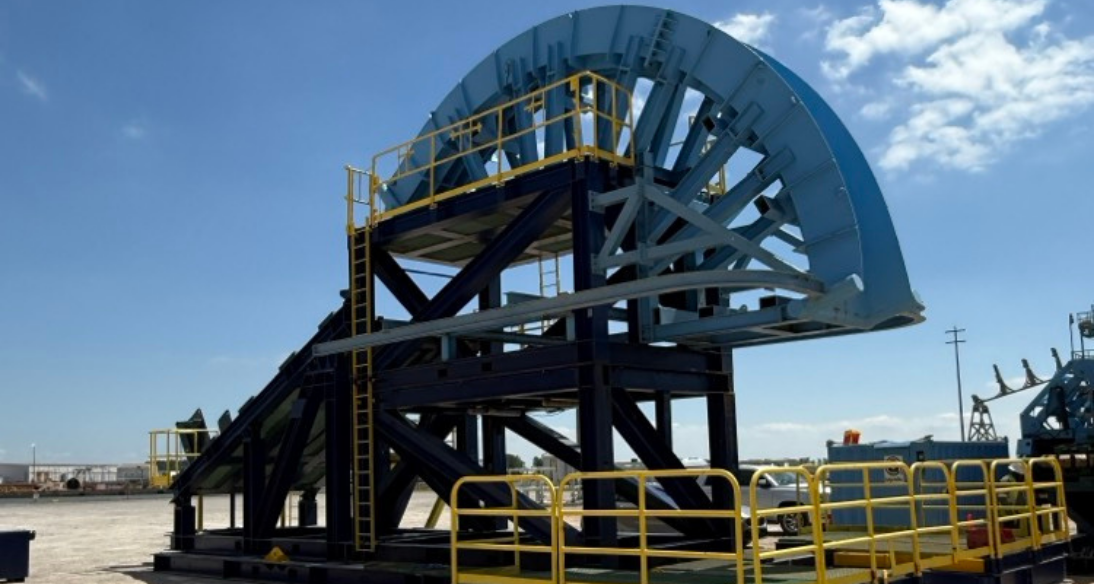

50Te SWL Horizontal Lay System

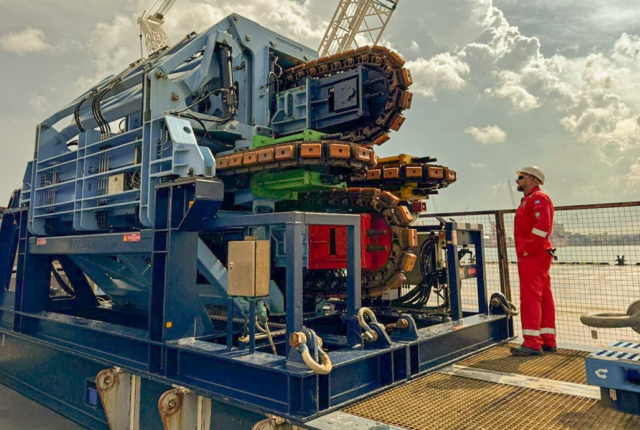

50Te four-track Tensioner

4m Overboarding Chute

Plus an Operational Personnel team comprising Lay Technicians, Supervisors and Winch Operators.

Motive supplies complete surf and cable lay solutions, including Horizontal Lay Systems (HLS), Tensioners, A&R Winches, plus all associated equipment. This integrated approach ensures clients receive a reliable, single-source solution engineered for maximum efficiency and safety.

This case study represented a major contract win for Motive in the USA. The solution centred around the Motive 50Te SWL Horizontal Lay System, providing a critical structure for efficient product handling during an umbilical lay - including dynamic, static armored and static unarmored - totalling 14,140m in the Gulf of America.

Our Solution

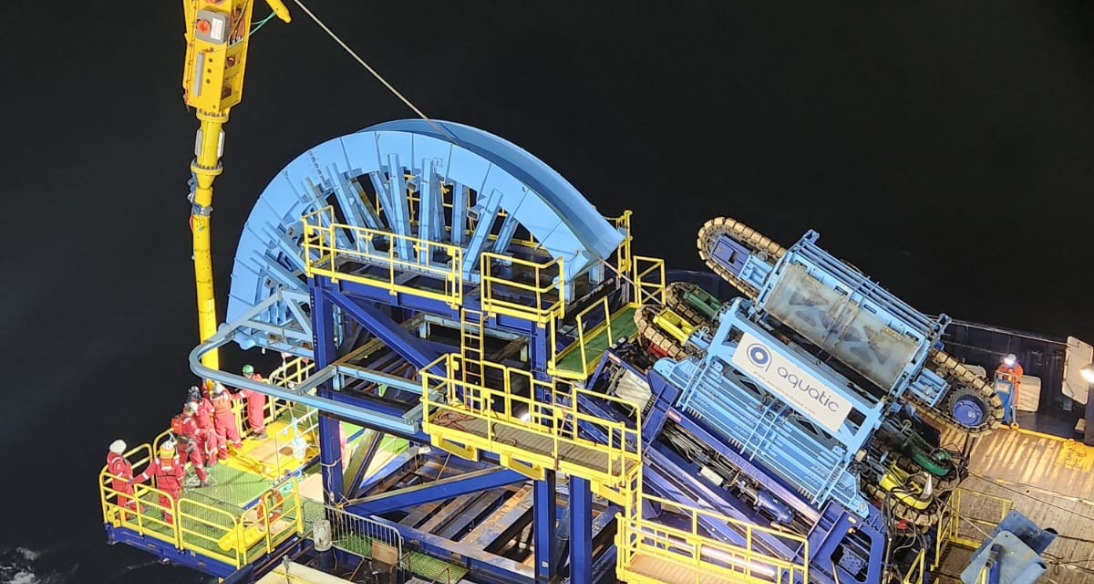

The Horizontal Lay System (HLS) was successfully assembled at the mobilisation site in Theodore, Alabama with onward transport to Port Fourchon, Louisiana where Motive Technicians carried out final preparations ensuring the horizontal lay system was vessel-ready for installation on arrival of the IRM, Survey and Light Construction Vessel.

Motive also supplied a 50Te four-track Tensioner, 4m Overboarding Chute and an operational Personnel team comprising Lay Technicians, Supervisors and Winch Operators.

On completion of the HLS lay spread installation, the vessel sailed to Panama City, Florida, where the umbilical was transpooled, and a tensioner test was conducted using an umbilical sample before heading offshore.

Cable Lay Expertise

Expert teams with decades of success in complex projects

Modular Benefits

Easier transport, fully adaptable to deck space

Single Source Solutions

Full equipment packages, available in-country

SAFETY-FIRST DESIGN

Designed to smoothly and safely handle extended lengths of product in a vertical plane, Operators benefit from secure work platforms that allow for the safe installation or removal of product jewellery, reducing manual handling.

Putting safety at the forefront of operations, all Motive HLS include integrated walkways, stairways, and handrails, allowing easy access to all operational areas.

MODULAR BENEFITS

Crucially for global projects, the Motive HLS range all benefit from a modular design. This significantly simplifies worldwide transport while allowing rapid, cost-effective mobilisation and demobilisation on-site. Clients can also benefit from using more readily available vessels of opportunity.

Highly portable for easier transport and faster mobilisation, the modular system is fully adaptable to suit available deck space. The HLS 30Te SWL hang-off worktable can be mounted to various vessel areas, including the moonpool, stern, or side, ensuring operational flexibility regardless of vessel configuration.

Conclusion

This case study highlights the effectiveness of a responsive service coupled with ‘all-in-one’, in-country solutions. The strategic turnkey response implemented by Motive enabled our client to benefit from easy mobilisation and smooth operations throughout the project.